Valve technology controls fluids in the complex industrial systems. These mechanical wonders control gases, liquids, and slurries in many applications, assuring accuracy and dependability. Butterfly valves and their upgraded versions stand out for their distinctive design, efficiency, and adaptability.

Bi-directional valves, butterfly valves, and high-performance valves are explained in this blog. It simplifies their operations, structures, and industrial tasks. This blog aims to explain their differences and why they matter by distinguishing them and studying their processes.

The valve you choose affects energy efficiency, maintenance, and dependability. The valves make flow control smooth and reliable, improving system integrity and performance when correctly matched to an application.

What Are Bi-directional Valves?

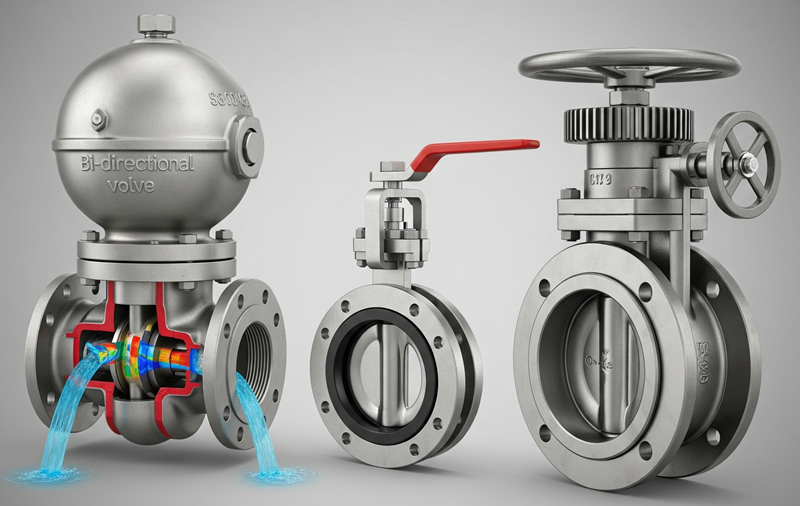

Modern flow systems need bi-directional valves to enable fluid to flow in both directions safely and efficiently. These unique valves allow fluid flow in either direction with equal efficiency, unlike regular valves. They shut off and function leak-free, thanks to a central sealing mechanism that can resist pressure differentials from both directions.

Their strong design generally uses modern sealing technologies to retain integrity under various situations. Bi-directional valves are used in water treatment, chemical processing, and power systems for flexibility and tight sealing. Their versatility may restrict their ability to handle harsh pressures or abrasive media, depending on the building materials. However, its dual-flow capacity provides unsurpassed ease and control in dynamic operating conditions.

Features and Benefits of Bi-directional Valves

● Allows fluid flow in both forward and reverse directions

● Ensures a tight shut-off under variable pressure conditions

● Reduces the need for directional valve installations and planning

● Enhances operational flexibility in dynamic flow systems

● Maintains sealing integrity from either inlet orientation

● Simplifies piping layouts with dual-flow functionality

● Minimizes downtime during flow direction changes

● Supports bidirectional pressure without performance loss

● Optimizes space with compact and versatile design

● Increases safety with consistent bi-directional performance

● Handles fluid reversal without valve repositioning requirements

● Improves system efficiency in multi-directional applications.

Understanding Butterfly Valves

Butterfly valves enhance industrial pipes with their elegance and utility. These valves gently control fluid flow using a disk on a central stem in a cylindrical body. The disk turns perpendicular to the flow and closes securely, but when aligned, it enables free flow. This basic mechanism responds quickly and controls efficiently with little space.

Butterfly valves come in many designs for installation. The wafer-type nests between flanges, whereas the lug-type has threaded lugs for isolation. This double-flange design offers reliable sealing and stability under heavy loads or crucial activities. Each variety meets a certain industrial purpose precisely.

Benefits of Butterfly Valves

● Compact design

● Ideal for space-saving installations

● Quick quarter-turn operation for fast control

● Lightweight structure reduces support requirements

● Low pressure drop across the open valve

● Suitable for throttling and shut-off functions

● Simple construction enables easy maintenance

● Cost-effective solution for large pipelines

● Available in various mounting configurations

● Compatible with manual or automated actuators

● Reliable sealing with minimal leakage risk

● Versatile use across multiple fluid types

● Efficient flow regulation in large systems.

High-Performance Butterfly Valves (HPBV)

HPBVs control flow with technological finesse and mechanical robustness. These valves perform well in severe environments. Their sturdy, double-offset design reduces friction for smoother rotation and improved sealing in harsh conditions. Valve materials are of high quality for corrosion resistance and mechanical strength. Metal or strong sealing systems can endure temperature fluctuations and high flow rates. HPBVs provide long-term performance stability with torque efficiency and minimal wear.

Power generation, petrochemicals, and maritime applications need consistent performance for safety and continuity. High-Performance Butterfly Valves create strong networks by managing flow and control in complicated fluid systems.

Features and Benefits of High-Performance Butterfly Valves

● Handles higher pressure and temperature than standard valves

● Offers reliable sealing in both flow directions

● Reduces wear through advanced offset disc design

● Ensures smooth operation with lower torque requirement

● Provides extended service life in harsh environments

● Compatible with a wide range of actuators

● Maintains a tight shut-off under extreme conditions

● Suitable for critical and high-demand industrial applications

● Minimizes maintenance through durable construction materials

● Delivers efficient flow control with compact footprint

● Resists corrosion in aggressive chemical processes

● Enhances system safety with dependable performance.

Key Differences across the Valves

All the above valves have various structural and operational characteristics in fluid control. Bi-directional valves gently enable flow in both directions, avoiding readjustment. In systems with frequent reversals, they provide reliable shut-off and balanced control.

Classic butterfly valves with disc-and-stem designs are simple and affordable. Low-to-moderate pressure systems work well with their quick quarter-turn flow regulation. Its lightweight and compact design suits general-purpose applications.

Advanced engineering makes high-performance butterfly valves stand out. They flourish in harsh pressures and temperatures where accuracy and endurance are essential. They seal better, minimize friction, and last longer due to their double-offset design.

Each valve has a purpose—flow control, pressure needs, and intentional design and investment.

How to Choose the Right Valve?

● Evaluate system pressure for suitable valve strength requirements

● Check the maximum temperature the valve must withstand reliably

● Identify the fluid type and its chemical composition

● Assess available space for proper valve installation clearance

● Ensure compatibility with surrounding piping and components

● Consider the valve material based on corrosion resistance needs

● Match the actuation method with the system control specifications

● Review maintenance frequency and ease of servicing

● Determine the sealing type required for zero-leak performance

● Verify the valve's response time for operational accuracy

● Analyze total lifecycle cost beyond initial investment

● Choose a design that meets industry standards and certifications.

Concluding Remarks

Indian industrial valve makers such as Advance Valves are known worldwide for their precision, creativity, and durability. They employ advanced automation, material science, and technology. Skilled personnel and smart equipment make valves for the world's most demanding industries in massive production facilities.

From casting to testing, these firms follow international standards. They master customization, providing customized solutions for diverse industrial demands. They push pressure handling, sealing efficiency, and corrosion resistance frontiers with constant R&D.

Indian valve manufacturers set new benchmarks and standards. Their products reliably pass through power plants, refineries, chemical facilities, and maritime systems. They passionately promote their country by combining technological expertise with a global vision.

Also Read : Actuated Butterfly Valves for Brilliant Effectiveness and Unfaltering Dependability