Butterfly valves are immensely important equipment playing a crucial role in controlling the internal flow of different types of fluids effectively and efficiently. They carry it out by rotating a disc into a quarter turn. These valves are named after butterflies due to the way they function giving the impression of a butterfly. The shaft that the valves contain represents the body and the disk on top acts quite like the wings of a butterfly.

Generally, the position of the disc remains either parallel or perpendicular to the fluid’s flow. When it comes to the ability to seal the pressure within, these valves manufactured and supplied by the top butterfly valves manufacturers in India, are quite different from other types of valves. Primarily used in pumping stations along with many others, butterfly valves are very compact in size, unmatched in performance, and make the installation process also very easier.

Owing to the vast applications across sectors and industries the world over, butterfly valves are always in huge demand. According to a research report recently published by the Research Dive, the global butterfly valve market is going to witness a whopping growth at a steady CAGR of 5.9% to reach the mark of $14,108.3 million by 2028.

A butterfly valve is segregated into four essential parts known as the body, disc, stem, and seat. The body is where two lines can be adjoined in a structure known as a lug or even wafer-type which then, at that point, prompts the valve disk. This portion is where the progression of fluid is controlled and this segment as a rule needs to have a steadiness for the better flow, and working force of the valve. The next part is the stem that contains a one or two-piece shaft design, and the last section is the seat of the valve wherein the supply gets shut off.

Variants of Butterfly Valves

The plumbing and piping segment makes use of a large number of valves for a smooth and hassle-free supply of fluid across areas. Butterfly valves are also the most prominent among them and are also divided into sub-divisions concerning certain requirements across applications. A butterfly valve is broadly categorized into three different types:

• Plastic lines

• Rubber lines, and

• Metal.

The plastic line valves come with an amazing resistive capacity and that’s why they are comprehensively used in applications such as harsh chemicals and also for sanitary purposes. Rubber line valves, on the other hand, are considered to be a more economical option and these valves function under low temperatures while remaining untarnished. When it comes to metal ones, they find applications in situations that call for the presence of a high degree of temperature or even pressure.

Major industries that rely on butterfly valves

Manufactured and supplied by the top actuated butterfly valves manufacturers, butterfly valves have become the lifeline of many industries due to a large number of reasons. These valves are extremely convenient yet have an outstanding capability of controlling the flow of fluid across industries. Some of the top industry segments that rely on these valves include the following:

• Water Supply

• Power Generation

• Food Processing

• Vacuum Service

• Chemical and Oil Industries

• Treatment of Wastewater

• Provision of Compresses Gas and Air

• Lubrication Systems.

Given below are some general applications of butterfly valves

Garden Irrigation Systems

These frameworks are often composed of PVC or CPVC pipes, with elbows, tees, and couplings interfacing everything. They run adjoining or over patio gardens and drip water, in some cases, enhanced with supplements, onto the plants and vegetables beneath. This is accomplished through many methods, including drilled pipes and perforated hoses. Butterfly valves can be used here effectively and efficiently to start and stop the flow in these garden irrigation systems. They might isolate specific parts of the system so that you can water only the thirstiest areas of the garden. Butterfly valves being inexpensive are very popular for such applications.

Pressurized Applications

Designed and manufactured by the makers of valves in India, butterfly valves are quite a panacea for applications wherein either gases or pressurized air are involved. These applications can take their toll on valves particularly when they open slowly. But, if you make use of an automatic actuation on the valve, it will start opening almost instantly.

Space-Restrictive Applications

In case you are still thinking about where you can make use of the butterfly valve best, then systems and frameworks running short on space can be the ideal destination. Installing an effective and efficient piping system in small spaces can be a tough errand. Pipes and fittings don’t occupy much space, but valves and strainers in such tight spaces might prove to be very clunky. Here at this juncture, butterfly valves made and supplied by the top manufacturers of valves can be of immense significance. Butterfly valves call for a lesser amount of space when compared to ball valves and many other types of shut-off valves. These properties and attributes make them perfectly suitable for performance-packed flow control across tight spaces.

Salient advantages of butterfly valves

• A complete closure or opening of the valve due to a 90-degree rotation

• They also have a reduced level of wear

• Low direct operating costs

• Butterfly valves can be installed across applications where space is a big issue

• These valves come with a very compact design in comparison to other types of valves

• Butterfly valves call for lesser maintenance

• Butterfly valves are relatively inexpensive to build, and

• They are easy and fast to open.

Concluding Remarks

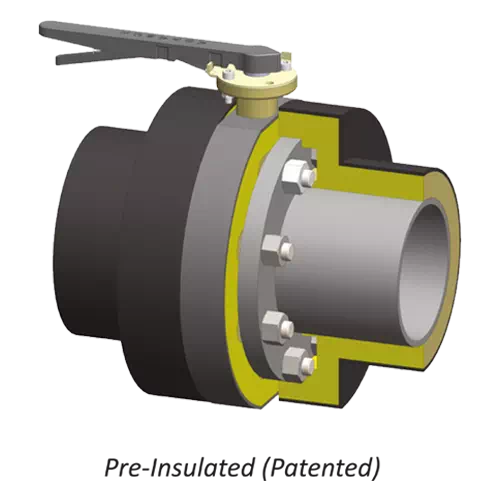

Advance Valves Group has been providing world-class technology solutions to global customers for the past 36 years through a well-oiled network of offices and dealers across India, the Middle East, the United States, and Europe. Right since its inception, the company has been a Pioneer & Innovator in its wide range of Valves like Dual Plate Check Valves, Balancing Valves, Triple Eccentric Butterfly Valves & Valves with Pre-Insulation.